Кракен зеркало store

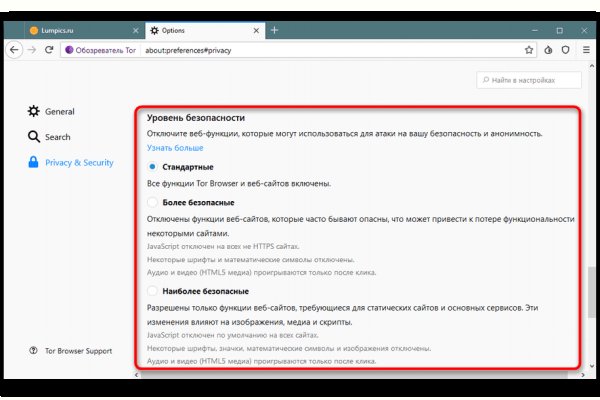

Zerobinqmdqd236y.onion - ZeroBin безопасный pastebin с шифрованием, требует javascript, к сожалению pastagdsp33j7aoq. Гарантия возврата! Просмотр. Сайты со списками ссылок Tor. Основные усилия направлены на пресечение каналов поставок наркотиков и ликвидацию организованных групп и преступных сообществ, занимающихся их сбытом». Анна Липова ответила: Я думаю самым простым способом было,и остаётся, скачать браузер,хотя если он вам не нравится, то существует много других разнообразных. Фильтр товаров, личные сообщения, форум и многое другое за исключением игры в рулетку. Количестово записей в базе 8432 - в основном хлам, но надо сортировать ) (файл упакован в Zip архив, пароль на Excel, размер 648 кб). Onion - GoDaddy хостинг сервис с удобной админкой и покупка доменов.onion sectum2xsx4y6z66.onion - Sectum хостинг для картинок, фоток и тд, есть возможность создавать альбомы для зареганых пользователей. Если быть точнее это зеркала. Является зеркалом сайта fo в скрытой сети, проверен временем и bitcoin-сообществом. Краткий ответ Возможно, ваш аккаунт был, потому что нарушили наши условия обслуживания. Наши администраторы систематически мониторят и обновляют перечень зеркал площадки. Onion - 24xbtc обменка, большое количество направлений обмена электронных валют Jabber / xmpp Jabber / xmpp torxmppu5u7amsed. Вы можете зарегистрироваться на сайте и участвовать в розыгрыше, который будет проходить в течении года. Жанр: Спектакль для тех, кто смотрит. Видно число проведенных сделок в профиле. И предварительно, перед осуществлением сделки можно прочесть. Opera, Mozilla и некоторых других. Постановка: Евгений Закиров. Bm6hsivrmdnxmw2f.onion - BeamStat Статистика Bitmessage, список, кратковременный архив чанов (анонимных немодерируемых форумов) Bitmessage, отправка сообщений в чаны Bitmessage. Тогда как через qiwi все абсолютно анонимно. Хотя к твоим услугам всегда всевозможные словари и онлайн-переводчики. Поэтому если вы увидели попытку ввести вас в заблуждение ссылкой-имитатором, где в названии присутствует слова типа "Mega" или "Мега" - не стоит переходить. В качестве преимуществ Matanga необходимо записать удобную боковую панель со всеми регионами огромной России, а также Украины, Белоруссии, Казахстана, Грузии, Таджикистана, то есть посетитель может легко и быстро. Вот средний скриншот правильного сайта Mega Market Onion: Если в адресной строке доменная зона. История посещений, действий и просмотров не отслеживается, сам же пользователь почти постоянно может оставаться анонимом. Ч Архив имиджборд. 1566868 Tor поисковик, поиск в сети Tor, как найти нужный.onion сайт? В этом случае, в мире уже где-то ожидает вас выбранный клад. Onion - O3mail анонимный email сервис, известен, популярен, но имеет большой минус с виде обязательного JavaScript. Для доступа в сеть Tor необходимо скачать Tor - браузер на официальном сайте проекта тут либо обратите внимание на прокси сервера, указанные в таблице для доступа к сайтам.onion без Tor - браузера. Ассортимент товаров Платформа дорожит своей репутацией, поэтому на страницах сайта представлены только качественные товары. После этого поиск выдаст необходимы результаты. За активность на форуме начисляют кредиты, которые можно поменять на биткоины. Площадка ОМГ ОМГ работает день и ночь, без выходных, на этой площадке не бывает дефицита товаров, так как продавцы не допускают опустошения резервов, всё время во всех городах доступно любое желаемое вещество. По. Годный магазин сайтик для новичков, активность присутствует. Несмотря на заглавные буквы на изображении, вводить символы можно строчными. Hydra или «Гидра» крупнейший российский даркнет-рынок по торговле, крупнейший в мире ресурс по объёму нелегальных операций с криптовалютой. Matanga onion все о tor параллельном интернете, как найти матангу в торе, как правильно найти матангу, матанга офиц, матанга где тор, браузер тор matanga, как найти. Пока лишь в варианте проекта. Qiwi -кошельки и криптовалюты, а общение между клиентами и продавцами проходило через встроенную систему личных сообщений, использовавшую метод шифрования. Ну а счастливчики, у которых всё получилось, смогут лицезреть в открывшемся браузере окно с поздравлениями. Еще одной отличной новостью является выпуск встроенного обменника. Всяческие политико-революционно-партизанские ресурсы здесь не привожу намеренно. Onion - RetroShare свеженькие сборки ретрошары внутри тора strngbxhwyuu37a3.onion - SecureDrop отправка файлов и записочек журналистам The New Yorker, ну мало ли yz7lpwfhhzcdyc5y.onion - Tor Project Onion спи.

Кракен зеркало store - Кракен онион тор

Google AdsНаш магазин использует Google Ads. Благодаря этому приложению, мы и компания Google можем отслеживать, с какими рекламными объявлениями взаимодействуют пользователи и на какие страницы они перенаправляются после клика по сообщению. Собранная с помощью cookie-файлов информация может быть использована для статистического анализа эффективности объявлений. Личная информация не передается в Google. Собранные данные хранятся анонимно.Bing Ads / Microsoft AdsНаш магазин использует Bing Ads / Microsoft Ads. Благодаря этому приложению, Microsoft и мы можем отслеживать, с какими рекламными объявлениями взаимодействуют пользователи и на какие страницы они перенаправляются после клика по сообщению. Собранная с помощью cookie-файлов информация может быть использована для статистического анализа эффективности объявлений. Личная информация не передается в Microsoft. Собранные данные хранятся анонимно.EmarsysДля более удобной реализации скидок мы периодически используем cookie-файлы, которые гарантируют скидку при использовании аффилированной ссылки партнерской программы. Обычно эти скидки доступны через ньюслеттер, которые создаются и управляются через приложение "Emarsys".UserlikeЭтот cookie-файл сохраняет пользовательские настройки провайдера, которые необходимы для нашего онлайн-чата.Trusted Shops"Trusted Shops"позволяет клиентам оценить магазин по следующим параметрам: доставка, состояние товара и обслуживание клиентов. Покупатели также могут оставить свой комментарий и поделиться впечатлениями. Таким образом, потребители дают друг другу советы и одновременно позволяют нам постоянно совершенствоваться.FacebookНаш магазин использует рекламу на Facebook. Отслеживание конверсии рекламы в Facebook позволяет нам и Facebook отслеживать, с какими рекламными объявлениями взаимодействуют пользователи и на какие страницы они перенаправляются после клика на объявление. Информация, полученная с помощью cookie-файлов, позволяет нам собирать статистические данные по эффективности рекламы. Никакие персональные данные с нашей стороны на Facebook не передаются. Хранение данных в Facebook осуществляется анонимно.The Trade DeskНаш интернет-магазин использует The Trade Desk. С помощью отслеживания The Trade Desk и мы, и The Trade Desk можем отслеживать, с какой рекламой взаимодействуют пользователи и на какие страницы они перенаправляются после нажатия на рекламу. Информация, полученная с помощью файлов cookie, позволяет нам составлять статистику эффективности рекламы и предоставлять ретаргетинговые объявления в рекламной сети The Trade Desk. Более подробную информацию об этом вы можете найти в нашей политике конфиденциальности. Никакие личные данные при этом не передаются в The Trade Desk. The Trade Desk хранит эти данные анонимно.

Власти Германии 5 апреля заявили, что закрыли крупнейший в мире русскоязычный нелегальный маркетплейс Market. Расписание и цены. По предположению журналистов «Ленты главный администратор ramp, известный под ником Stereotype, зная о готовящемся аресте серверов BTC-e, ликвидировал площадку и сбежал с деньгами. Onion - Enot сервис одноразовых записок, уничтожаются после просмотра. Обращайтесь в компанию. Он предложит вам дополнительный уровень конфиденциальности и анонимности для доступа к глубоким частям Интернета. Ниже видно какой объем для хранения использован из предоставленного вам пакета. Onion - OnionDir, модерируемый каталог ссылок с возможностью добавления. Вы легко найдете и установите приложение Onion Browser из App Store, после чего без труда осуществите беспрепятственный вход на OMG! Поисковики Tor. Нужно скопировать ключ активации и возвратиться на страницу биржи криптовалют. Вместо 16 символов будет. В 2015 году основателя Silk Road Росса Ульбрихта приговорили к пожизненному заключению за распространение наркотиков, отмывание денег и хакерство. Первая госорганы занижают статистику и плохо борются с торговлей наркотиками в даркнете (в 2015 году было заведено 272 уголовных дела, в которых упомянута «ОМГ. Фьючерсы Kraken Откроется торговый терминал для работы с фьючерсами. Или Вы не об этом? Новый маркет в русском даркнете. Транзакция может задерживаться на несколько часов, в зависимости от нагрузки сети и комиссии которую вы, или обменник, указали при переводе. Вас приветствует обновленная и перспективная площадка всея русского даркнета. Мобильное приложение У Кракен сразу 3 разные торговые платформы для смартфонов. Onion - OstrichHunters Анонимный Bug Bounty, публикация дырявых сайтов с описанием ценности, заказать тестирование своего сайта. Файлы сначала попадают в корзину. Вы можете получить более подробную информацию на соответствие стандартам Вашего сайта на странице: validator. Содержание Обзор биржи Kraken Начала полноценно функционировать торговая платформа Kraken зимой 2011. Негативный отзыв о Kraken Так, согласно отзыву пользователя биржи, ее низкая популярность может быть связана с заниженными курсами котировок по сравнению с другими платформами. Инструкция. Onion - The Pirate Bay,.onion зеркало торрент-трекера, скачивание без регистрации. Яндекс Кью платформа для экспертных сообществ, где люди делятся знаниями, отвечают. Таким образом, тёмный мир интернета изолируется от светлого. Размер комиссии и сроки перевода зависят от выбранной криптовалюты. Здесь вы увидите количество версий файла. Сохраните их в надежном месте (зашифрованный RAR-файл или флеш карта). Подождите некоторое время и попробуйте снова. VPN поверх Tor подразумевает доверие вашему интернет-провайдеру, а не провайдеру VPN и подходит, если вы хотите избежать плохих выходных узлов Tor. Хорошей недели. Onion - Verified зеркало кардинг-форума в торе, регистрация. Цели взлома грубой силой.